1、 Introduction to single-sided double-layer aluminum substrate:

Single sided double-layer aluminum substrate is a compact and high-performance circuit board with good pressure resistance, heat resistance, and corrosion resistance, which can meet the high-precision and high reliability requirements of electronic products. It has good insulation performance and can effectively prevent the leakage of current on the circuit board, ensuring the safety and reliability of electronic products. The single-sided double-layer aluminum substrate has good thermal conductivity, can effectively dissipate heat, and can effectively transfer heat to electronic components, thereby improving the working efficiency of electronic components. In addition, the single-sided double-layer aluminum substrate has good mechanical strength, can withstand impact, and extend the service life of electronic products.

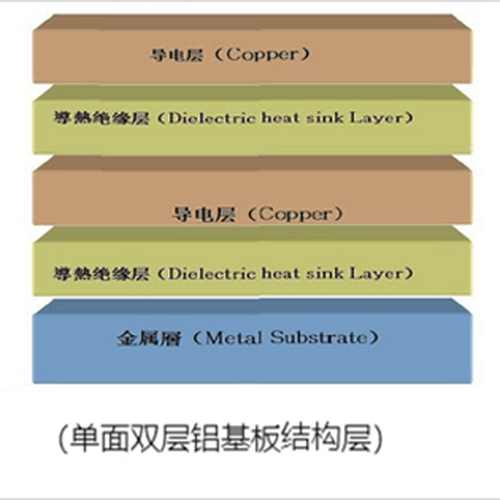

2、 Structural characteristics of single-sided double-layer aluminum substrate:

Single sided double-layer aluminum substrate is a new type of aluminum based composite plate with strong mechanical properties, corrosion resistance, and thermal stability. Its advantages lie in the good heat dissipation performance and high tensile strength of metal aluminum, with a tensile strength of over 200MPa and good bending resistance, which can effectively resist external forces. In addition, it has excellent heat resistance and can withstand temperatures up to 200 ℃, making it widely used in many high-temperature environments. In addition, the single-sided double-layer aluminum substrate also has good corrosion resistance, which can effectively resist external corrosion, thus achieving high-quality products. It is composed of two layers of circuit layers and aluminum based materials, with the upper layer being a complex and precise double-sided wiring, the lower layer being an aluminum plate, and the middle filled with thermal conductive adhesive. During the production process, a single-sided double-layer aluminum substrate composite structure is formed by high-pressure extrusion and hot pressing treatment.

3、 Production process and technical requirements for single-sided and double-layer aluminum substrate

Single sided double-layer aluminum substrate is a commonly used electronic component used for making electronic circuit boards. To make a single-sided double-layer aluminum substrate, it is necessary to master certain techniques. Below, we will introduce the production process and precautions for single-sided double-layer aluminum substrate. Firstly, it is necessary to prepare the raw materials for a single-sided double-layer aluminum substrate, usually using materials such as 5052 aluminum plate, glass fiber substrate, thermal conductive adhesive, etc., and then subjecting them to high-temperature hot pressing treatment to form a single-sided double-layer aluminum substrate. Secondly, it is necessary to design the circuit diagram and requirements on a single-sided double-layer aluminum substrate, and then perform laser etching to engrave the shape of the circuit diagram onto the aluminum substrate. Finally, testing is required to ensure the quality of the single-sided double-layer aluminum substrate. When making single-sided and double-layer aluminum substrates, it is also necessary to pay attention to the following points: firstly, choose suitable raw materials; Secondly, attention should be paid to the tensile strength of the aluminum substrate; The third is to ensure that the surface of the aluminum substrate is flat.

4、 Application fields and market prospects of single-sided and double-layer aluminum substrate

Single sided double-layer aluminum substrate is a multifunctional material with advantages such as good thermal conductivity, electrical insulation, corrosion resistance, wear resistance, and low noise. It can be widely used in industries such as aerospace, electronics, automation, power, and automobiles. Single sided double-layer aluminum substrate has good thermal conductivity and electrical insulation, which can be used for packaging and assembly of electronic components to improve the thermal control performance and reliability of electronic components. In addition, single-sided and double-layer aluminum substrates also have good corrosion resistance and wear resistance, which can be used in industries such as aerospace and automotive to improve product reliability and service life. With the increasing demand for high-performance materials in modern society, the application market of single-sided and double-layer aluminum substrates will further develop, and the market prospects are very promising.